Blog Post

Preventing Slips, Trips, and Falls in Underground Mining

Underground Team • Mar 24, 2021

Preventing STF from Underground Mining Mobile Equipment

In this blog post, we’ll go over the STF hazards and discuss how we can take preventive measures to reduce accidents in the mining field due to heavy fleets.

What Is Meant By Slips, Trips, and Falls (STF)?

Slips

- A slip refers to the situation when a worker’s foot accidentally slides on a working surface.

Trips

- Trips occur when an individual’s foot gets caught on obstruction while working on the field.

Falls

- Slips and trips lead to falls to other hazards in mining fields. Falls can happen on the same or lower levels, like when hauling yourself up to enter mobile mining equipment’s cab.

Causes of ‘Slips, Trips, and Falls’ Injuries

It has been concluded after a thorough research that a good percentage of the MSHA-issued health dangers were associated with fall risks between 2010 and 2017. Moreover, according to the evaluation

performed by the National Institute for Occupational Safety and Health (NIOSH), underground mining mobile equipment is the most significant cause behind STF-related injuries.

To put it into further context, around 26% of the non-fatal injuries related to hauling trucks (large trucks) happen due to slips, trips, and falls. Moreover, 16% of the injuries occur during maintenance and repairs. When the mineworkers were interviewed to get an idea regarding their opinions on the subject matter, they pointed out limited visibility, inadequate lighting, and faulty fleet handrails, the biggest causes of detrimental abrasions.

Based on the above facts and figures, NIOSH has accumulated a list of recommendations for promoting safe practices while working with underground mining mobile equipment:

1. A designated parking area free of hazardous ground conditions should be provided for mining mobile fleet drivers.

2. Adequate handholds must be equipped within the equipment to make it easier for the workers to ingress and egress from the fleet. Mammoth provides green safety handrails

that are safe to touch and stand on, encouraging a safe working environment.

3. Housekeeping supplies should be provided to mining workers at a safe, marked location for removing contaminants from the equipment.

4. Twenty lux of uniform illumination should be offered to improve the chances of detecting hazardous ground or ladder conditions.

5. It should be mandatory to maintain three points of contact when using ladders.

6. The underground mining mobile equipment should be regularly inspected for the maintenance of ingress and egress systems.

For more information regarding taking preventative measures for reducing STF occurrences, you can contact Mammoth Equipment through our website

or call us at 1 800 854 8291.

Share

Tweet

Share

Mail

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment

By Ryan Johnson

•

27 May, 2022

Whether you are a heavy equipment fitter, a mobile maintenance mechanic or a mobile maintenance superintendent , you know the work and time that goes into keeping the heavy diesel mobile equipment operational at your site. Maintenance can be planned or unexpected and involves many different projects, some of which are listed below: Haul Truck Rebuilds Preventative Maintenance Engine Changes Does your site have engine changes or complete rebuilds scheduled soon? Here is one thing our customers have been asking for:

By Ryan Johnson

•

11 Feb, 2022

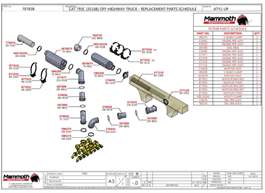

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793C haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 156-6237 2W-9078 156-6247 8X-3361 8X-3360 8X-3135 7C-3337 155-0528 242-8869 8X-3142 Mufflers 7E-6811 Brackets 8X-3130 8X-5103 8X-2850 8X-3128 8X-3132 Clamps 1W-4161 2W-8851 7E-8452 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793F haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 311-6213 311-6204 319-6019 311-6207 319-5307 291-9649 Flex Bellows 306-0297 Mufflers 7E-6811 Brackets 319-5918 293-7616 8X-3130 319-5912 Clamps 302-8136 337-1809 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

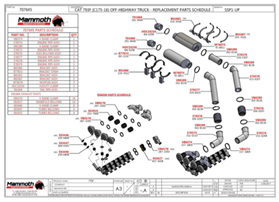

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793D haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the 3516B engine. This includes: Pipes 250-6082 250-6083 250-6084 250-6085 242-8869 8X-3142 Flex Bellows 242-0799 Mufflers 7E-6811 Brackets 8X-3130 242-0792 242-0783 Clamps 302-8136 1W-4161 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.