Blog Post

FreezeGard prevents heavy equipment from freezing up!

Josh Skinner • Aug 13, 2021

Prevent equipment freeze up with Mammoth’s FreezeGard

There is nothing worse than winter woes that come with frozen equipment.

Whether you work in the mobile maintenance department or are tasked with driving a vehicle that boasts a Tier 4 engine, frosty weather can force you to confront freeze up that compromises your equipment condition and functioning.

Industrial equipment is expensive, and when its components are exposed to cold climates and freezes up, it can result high costs in both trying to repair the parts of the machine and the labor.

How do I prevent heavy equipment from freezing up?

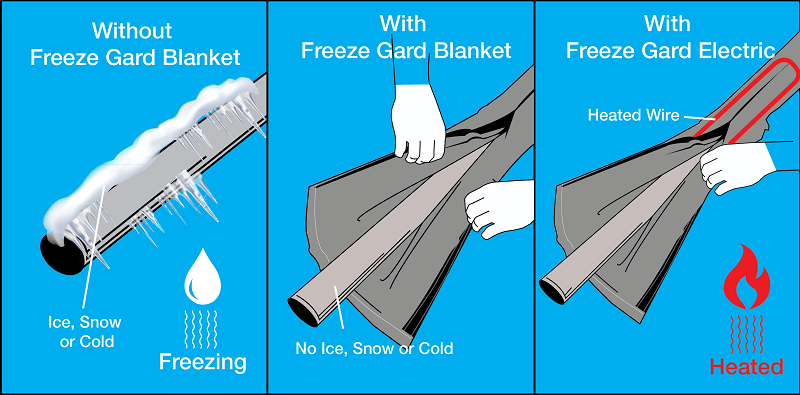

We suggest using FreezeGard product which is blanket that can be supplemented with heat trace wire. Using FreezeGard will:

o Reduce downtime caused by freezing up parts in the field

o Stops key parts of the machine from freezing up

o Help keep your machines running smoothly in cold climates

Can FreezeGard prevent DEF tanks from freezing up?

Let's take a step back and understand what DEF is. Diesel Exhaust Fluid (DEF) reduces emissions from mining and construction equipment most of which are equipped with Tier 4 engines. It is produced by combining deionized water and urea.

Diesel Exhaust Fluid (DEF) freezing occurs at temperatures lower than -11˚c.

Using FreezeGard blankets and heat trace we can help prevent freezing up on equipment allowing you (and your customers) to start using equipment sooner because there is no need to wait for it the DEF to thaw.

Hampering productivity and requiring extensive downtime for maintenance, frozen equipment is a problem you want to avoid! Prevention is better than cure, and there is no better way to address freeze-ups than ensuring they don’t damage your machines in the first place.

Here is how we helped a client with their electric drill by using FreezeGard:

FreezeGard, a heated insulation blanket by Mammoth Equipment is your best bet when it comes to thwarting freeze-ups and their unpleasant effects.

Our customer installed FreezeGard blankets on their electric drill to overcome water lines freezing up on the drill. This allowed them to continue operating in colder weather and save hours and hours of downtime.

What is FreezeGard?

Convenient and cost-effective, the FreezeGard is a waterproof, ultraviolet resistant product that consists of durable, long lasting silicon cloth. The blanket is flexible and can perform in temperatures ranging from -50C to +50C. These blankets are removable and reusable.

Convenient and cost-effective, the FreezeGard is a waterproof, ultraviolet resistant product that consists of durable, long lasting silicon cloth. The blanket is flexible and can perform in temperatures ranging from -50C to +50C. These blankets are removable and reusable.

Supplemented with a heat trace wire that protects instruments from being annihilated by the cold, the FreezeGard can be installed into multiple applications, such as pipes and hoses, DEF/water tanks, flanges, control panels, and valves, within an hour. Complemented with customizable blanket kits, the FreezeGard acts as a barrier between your equipment and the frost that threats it.

For more information, please feel free to contact us.

How is FreezeGard installed?

Co Our FreezeGard product is very easy to install as you can see in the image below. There is a hook and loop strip down each side of the blanket allowing you to wrap the blanket around your pipe or line and fasten.

Co Our FreezeGard product is very easy to install as you can see in the image below. There is a hook and loop strip down each side of the blanket allowing you to wrap the blanket around your pipe or line and fasten.

Give it a try on your equipment today!

Share

Tweet

Share

Mail

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment

By Ryan Johnson

•

27 May, 2022

Whether you are a heavy equipment fitter, a mobile maintenance mechanic or a mobile maintenance superintendent , you know the work and time that goes into keeping the heavy diesel mobile equipment operational at your site. Maintenance can be planned or unexpected and involves many different projects, some of which are listed below: Haul Truck Rebuilds Preventative Maintenance Engine Changes Does your site have engine changes or complete rebuilds scheduled soon? Here is one thing our customers have been asking for:

By Ryan Johnson

•

11 Feb, 2022

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793C haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 156-6237 2W-9078 156-6247 8X-3361 8X-3360 8X-3135 7C-3337 155-0528 242-8869 8X-3142 Mufflers 7E-6811 Brackets 8X-3130 8X-5103 8X-2850 8X-3128 8X-3132 Clamps 1W-4161 2W-8851 7E-8452 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793F haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 311-6213 311-6204 319-6019 311-6207 319-5307 291-9649 Flex Bellows 306-0297 Mufflers 7E-6811 Brackets 319-5918 293-7616 8X-3130 319-5912 Clamps 302-8136 337-1809 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793D haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the 3516B engine. This includes: Pipes 250-6082 250-6083 250-6084 250-6085 242-8869 8X-3142 Flex Bellows 242-0799 Mufflers 7E-6811 Brackets 8X-3130 242-0792 242-0783 Clamps 302-8136 1W-4161 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.