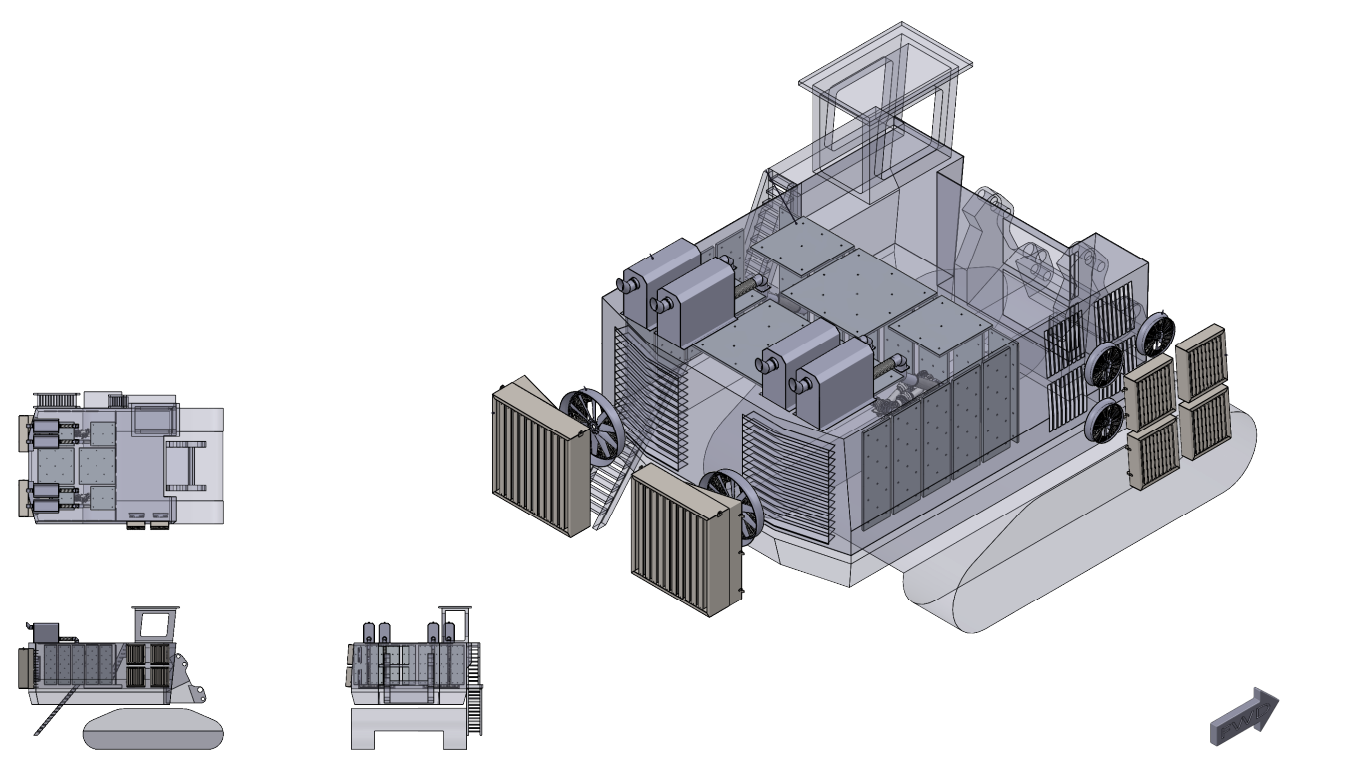

Caterpillar 6050: Air Intakes, Blankets / Thermal Insulations, Exhaust Systems and Sound Attenuation

The Caterpillar 6050 is one of the safest, fastest, and easiest hydraulic shovels on the market, making every load count. However, despite its exceptional design and production quality, components do deteriorate and fail over time.

The good news is that Mammoth Equipment engineers a variety of cutting-edge air intake, thermal insulations, exhaust systems, and sound attenuation upgrades. If you are looking to properly maintain and upgrade your Caterpillar 6050 for optimal performance, you are in the right place!

We will tell you everything you need to know about how our Caterpillar 6050 upgrades can benefit your Cat 6050.

Caterpillar 6050 Air Intakes

The stock air intake system works tirelessly in harsh conditions on Cat 6050 excavators. Over time, components will deteriorate and restrict airflow, reducing efficiency.

- Our heavy-duty upgrades feature premium-grade filtration media that captures 99% of fine dust and debris.

- Larger-diameter tubing maintains optimal airflow even when filters are blocked.

- Quick-release couplers permit swift filter changes, lowering downtime.

- Computational fluid dynamics optimization improves airflow and maximises torque and power.

Caterpillar 6050 Blankets / Thermal Insulations

Keeping the Cat 6050's engine compartments and hot surfaces shielded from heat damage helps extend component life. Mammoth’s purpose-built thermal covers are designed to reduce touch surface temperatures by up to an impressive 80%.

- Thermal covers have a hydrophobic silicon outer layer – preventing flammable fluid absorption.

- Built with hot facing materials proven to have no combustion point - thus making them safest in the entire mining industry.

- Our thermal covers are among the most tried and tested for mining equipment in the world.

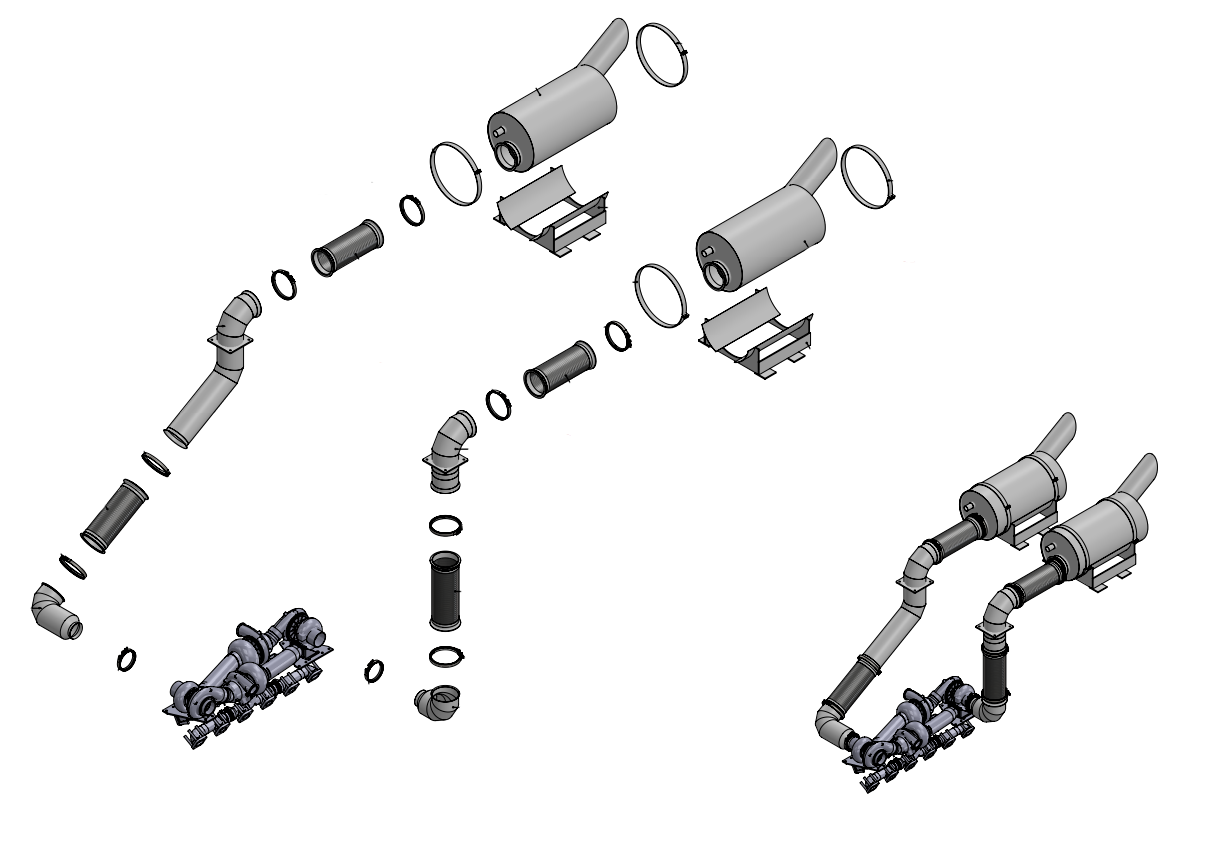

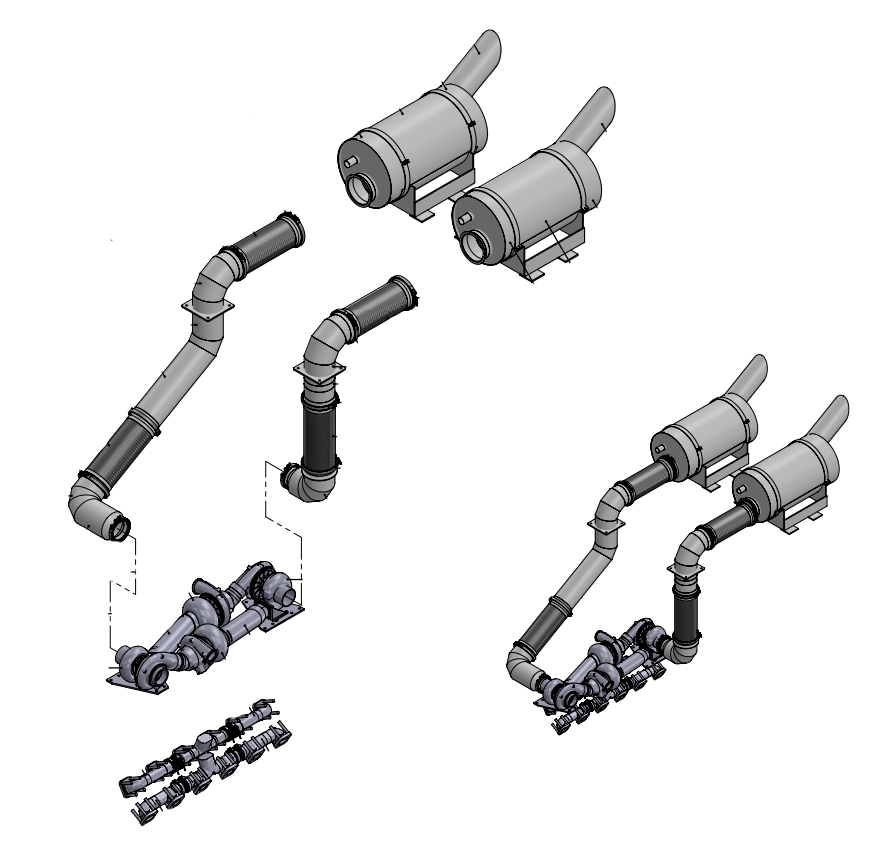

Caterpillar 6050 Exhaust Systems

A robust exhaust system is crucial for expelled gas flow on the CAT 6050. Our heavy-duty direct fit exhaust systems for the CAT 6050 are guaranteed to fit existing brackets, they’re built to last - and even outlast OEM.

- Easy Part Number cross referencing (OEM # and Mammoth Part #) for efficient upgrades and maintenance.

- On-request custom drawings with material # labelling services.

- Again, all exhaust system parts offer direct fit replacement (as you can use existing OEM bracketry).

Caterpillar 6050 Sound Attenuation

Continual exposure to high noise can pose a health hazard to on-site mining staff and the local community, especially during maintenance. Our acoustic packages precisely attenuate noise levels at the source.

- Staged attenuation solutions enable you to meet noise boundary requirements effortlessly.

- Maintenance-friendly designs with a focus on efficiency, simplicity, and accessibility.

- Low back pressure systems are designed to decrease mechanical stress on the engine and its related components.

In summary, our Caterpillar 6050 upgrades optimise efficiency, prolong component life, lower costs and most importantly, improve safety.

If you can’t quite find the information you are looking for, or if you have a specific question about our Caterpillar 6050 air intakes, blankets, exhaust systems, and/or sound attenuation upgrades, please do not hesitate to contact us today. One of our knowledgeable advisors will gladly answer any and all of your questions and point you in the right direction.