Blog Post

Importance of Exhaust Wrap Kits for Underground Mining Equipment

Ryan Johnson • May 27, 2021

Exhaust Wrap kits

Underground mining is one of the toughest jobs on the planet. The people and equipment employed for underground mining boast a great temperament and expertise of working at the roughest and toughest sites. Besides its great difficulty, underground mining is also a challenging job for its intrinsic safety issues.

Underground fires, for instance, are one of the leading concerns when it comes to drilling and mining from the layers of the earth beneath the ground surface. We need to mention here that only combustible ores are not responsible for underground fire mines. Spontaneous combustion

and equipment malfunction can also cause fires.

Equipment Malfunction and Spontaneous Combustions Are Not Always Avoidable

Underground mining equipment operates in some of the toughest conditions in many senses. They entail intensive use of 24/7 and 365. Moreover, they continuously operate in significantly high ambient temperatures (the deeper the mine, the higher the temperature).

Moreover, poor visibility, spillages, and breakaways within the mine always put the equipment in the line of powerful falls and impacts. Therefore, oil, fuel, and hydraulic lines of rigs and drillers are always prone to develop ruptures and split despite practicing due diligence and fulfilling compliance requirements.

On top of that, the fuel and other hydraulic fluids used in the equipment have relatively low auto-ignition temperature points. So, if equipment’s fuel pipes or fluid lines even develop a pinhole rupture spraying a thin stream of oil/fluid/fuel on the hot exhaust components of the equipment, it can lead to a nasty fire.

Exhaust Wrap Kits— Prevent Fires and Improve Worker and Equipment Safety

To break the chain of events discussed above, drilling and mining equipment manufacturers have developed exhaust wrap kits. These wrap kits insulate the exhaust lines and other hot components of the equipment so that oil, diesel, or hydraulic fluid spills and sprays don’t lead to underground mine fires.

Qualities of a Good Exhaust Wrap Kit

Any reliable mining and drilling equipment contractor also offers top-of-the-line exhaust wrap kits. Look for these features to get the best exhaust wrap kits for underground drilling and bolting equipment.

- They are easy to install— don’t need an extensive workforce and working hours for the installation.

- They are removable so that routine exhaust component inspections can be carried out.

- They provide excellent coverage through the exhaust’s outer surface that remains impenetrable by fluids.

- They can be adjusted and modified for different exhaust routing configurations.

- They boast an extended operating life— no quick replacements needed.

Mammoth Equipment and Exhausts— A Place that Offers Top-of-the-line Exhaust Wrap Kits

At Mammoth Equipment and Exhausts, we don’t just provide mining tools and equipment. We also offer ingenious safety products for the equipment. This is why you can also find top-quality exhaust wrap kits at Mammoth. Whether it is Maclean 928 Bolter, Sandvik Axera, Atlas Copco (Epiroc) 282 Boomer, or any other drilling rig, you can find its exhaust wraps at Mammoth.

We also offer customized wrap solutions for individual exhaust components and different exhaust routings. From engine manifold to tailpipe and muffler to purifier, we provide kits that completely wrap the total exposed exhaust surface of underground mining equipment.

To order exhaust wrap kits for your drilling and bolting equipment at a quick turnaround, get in touch with Mammoth Equipment through our website

or call us at 1 800 854 8291.

Share

Tweet

Share

Mail

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment

By Ryan Johnson

•

27 May, 2022

Whether you are a heavy equipment fitter, a mobile maintenance mechanic or a mobile maintenance superintendent , you know the work and time that goes into keeping the heavy diesel mobile equipment operational at your site. Maintenance can be planned or unexpected and involves many different projects, some of which are listed below: Haul Truck Rebuilds Preventative Maintenance Engine Changes Does your site have engine changes or complete rebuilds scheduled soon? Here is one thing our customers have been asking for:

By Ryan Johnson

•

11 Feb, 2022

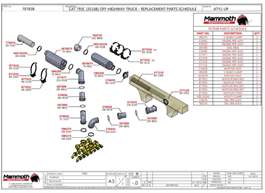

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793C haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 156-6237 2W-9078 156-6247 8X-3361 8X-3360 8X-3135 7C-3337 155-0528 242-8869 8X-3142 Mufflers 7E-6811 Brackets 8X-3130 8X-5103 8X-2850 8X-3128 8X-3132 Clamps 1W-4161 2W-8851 7E-8452 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

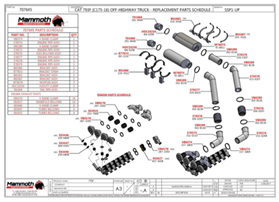

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793F haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 311-6213 311-6204 319-6019 311-6207 319-5307 291-9649 Flex Bellows 306-0297 Mufflers 7E-6811 Brackets 319-5918 293-7616 8X-3130 319-5912 Clamps 302-8136 337-1809 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793D haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the 3516B engine. This includes: Pipes 250-6082 250-6083 250-6084 250-6085 242-8869 8X-3142 Flex Bellows 242-0799 Mufflers 7E-6811 Brackets 8X-3130 242-0792 242-0783 Clamps 302-8136 1W-4161 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.