Exhaust Rebuild Kits – Save Money, Higher Quality

Whether you are a heavy equipment fitter, a mobile maintenance mechanic or a mobile maintenance superintendent, you know the work and time that goes into keeping the heavy diesel mobile equipment operational at your site.

Maintenance can be planned or unexpected and involves many different projects, some of which are listed below:

- Haul Truck Rebuilds

- Preventative Maintenance

- Engine Changes

Does your site have engine changes or complete rebuilds scheduled soon?

Here is one thing our customers have been asking for:

Exhaust Rebuild Kits

What is an Exhaust Rebuild Kit?

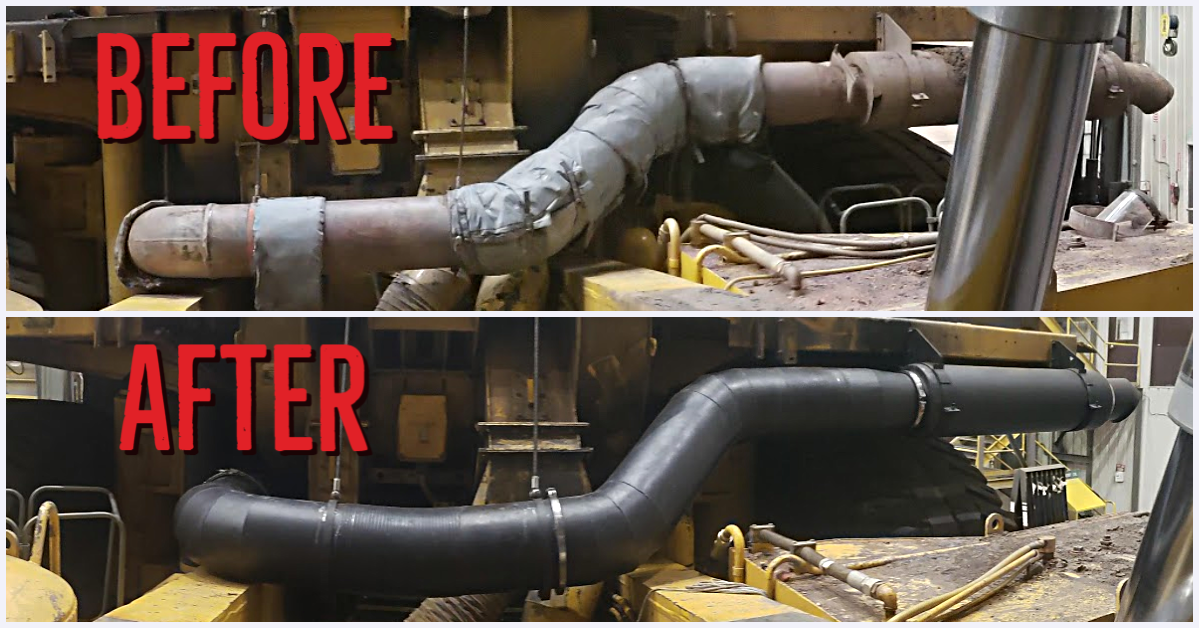

Mammoth Equipment exhaust rebuild kits are a complete replacement exhaust system for your piece of equipment. The kits are a direct fit to your equipment so there is no equipment modification required and every piece you need for a new exhaust system is included in this kit so you don’t need to worry about being short on any parts.

Why should I use Exhaust Rebuild Kits?

As you’d know, it’s often found exhaust parts need to be replaced when changing an engine or rebuilding a haul truck. Mammoth Equipment has developed an easy-to-use exhaust rebuild kits for all makes and models of haul trucks including Caterpillar, Komatsu, and Liebherr. Our product is known for superior quality and greater longevity compared to other suppliers.

- No need to wait until the haul truck is in the shop to determine parts needed

- No need to waste time inspecting rusted tubes and clamp connections

- No sifting through parts diagrams and writing out tedious RFQ’s

- Proactive change out on exhaust saves costs in the field

- Higher quality parts that last longer

- Manufactured in North America

How do I know the Mammoth Equipment Exhaust Rebuild Kit will fit my equipment?

Mammoth Equipment has a library of equipment drawings that our in-house innovation team has build up. Tell us the make and model of your equipment along with the serial number sequence and we’ll match that up with our drawings.

We will send you a copy of our drawing for you to check over and make sure it lines up with your equipment configuration.

Mammoth Equipment also has a guarantee. We guarantee a direct fit on our products. No modifications to equipment required.

It's easy to order!

When you’re ready…

- Only one part number to order (this includes all the parts you need in one complete kit)

- Your kit will be shipped in a robust crate (set it right next to the machine if you like!)

- No modifications to the haul truck needed – guaranteed direct fit

Contact the Mammoth Equipment team today!

P: 800.854.8291

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment