Global Supply Chain Shortage for Mining Industry

Many mine sites globally are in remote locations and the importance of keeping supply chain open and flowing without delays, shortages and infrequencies is paramount. To add to this is the growing challenges of COVID-19 and material shortages, which has led to many being faced with a shortage of material supply.

The second half of 2021 has seen demanding and has thrown curves for key components in keeping mining operations running smoothly without interruption or delay. These dramatic variations, coupled with the changing availability of commodities, pose a unique challenge for supply chains across the globe.

Understanding the Problem

It is also not easy for remote mines to change or set up new vendors for equipment, supplies and other metal accessories. A vendor who is currently experiencing supply issues themselves can hinder the entire production process in a mine and lead to multiple disruptions.

Mining companies need vendors to support them with their needs when they need it.

Dependency on one supply source can create a risk for mining companies as they grapple with supply when there is a shortage.

How Mammoth Makes a Difference

Mammoth hears of a gap in global supply chain schedules and where mining vendors are falling short. Here are a few of the ways that Mammoth has stepped up to meet this current challenge:

- Increased number of warehouses and distribution points

- Our products are manufactured in Winnipeg, Canada, are shipped across North America and are stocked in warehouses in Winnipeg, Edmonton, Denver, and Elko.

- More stocked warehouses coming soon

- Increased inventory with more distribution points

- Increased production space

In addition to this, we have a brand new production facility under construction that we hope to move into in spring of 2022.

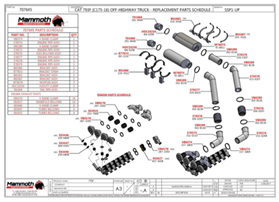

We recognize the importance of equipment availability to meet production targets. If there are currently components that are a common failure and a constraint on your operation, please feel free to reach out to us. Meanwhile, we look forward to continuing to support your operations with complete exhaust systems, replacement exhaust parts (pipes, mufflers, DPF’s, SCR’s, flex bellows), air intake, thermal exhaust blankets, handrails and much more.

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment