Prepare for Summer: Engine Bay Overheating

Is your engine bay overheating causing wiring harnesses and hoses to melt?

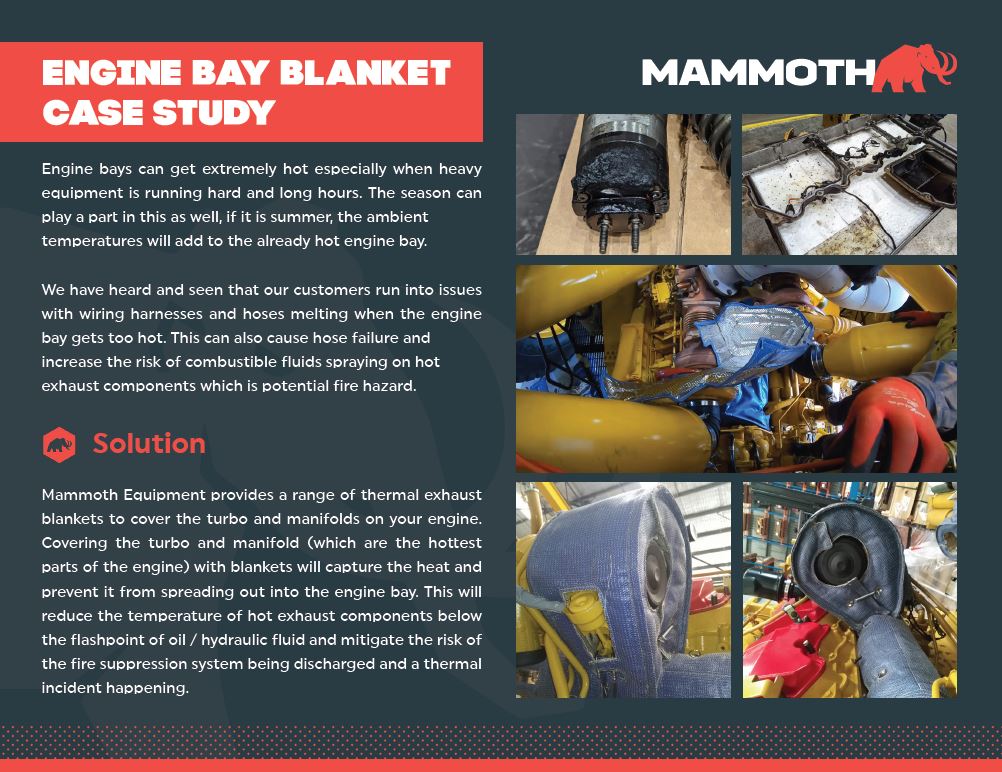

Engine bays on mobile heavy equipment get extremely hot when they are running hard, long hours and sometimes to the point of melting electrical wiring in the engine bay – does this sound familiar to you?

Engine bays that get too hot can also cause hose failure and increase the risk of combustible fluids spraying on hot exhaust components which is a potential fire hazard.

We have both heard and seen this onsite at our other clients.

Many times, we are called to site to discuss how we can safeguard their mobile equipment by insulating the hot exhaust components, protecting the equipment from fires.

SOLUTION:

Mammoth Equipment provides a range of thermal exhaust blankets to cover the turbo and manifolds on your engine. Covering the turbo and manifold (which are the hottest parts of the engine) with blankets will capture the heat and prevent it from spreading out into the engine bay.

This will reduce the temperature of hot exhaust components below the flashpoint of oil / hydraulic fluid and mitigate the risk of the fire suppression system being discharged and a thermal incident happening.

CASE STUDY:

BENEFIT TO YOU:

By insulating the hot exhaust components (turbo and manifold) some of the other benefits include:

- Lower engine bay temperatures

- Less stress on nearby components – hoses, harnesses, starters, alternators, etc.

- Less stress on operator cab air conditioning systems

- Quicker time for mechanics to be able to start work on equipment when it comes in the shop

Contact the Mammoth team today to learn more about our turbo and manifold thermal blanket kits that are available.

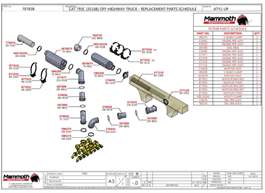

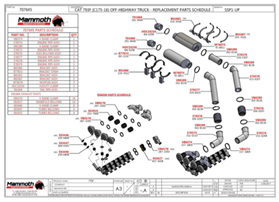

CHOOSE YOUR EQUIPMENT MAKE & MODEL:

We have a library of equipment drawings, each drawing is unique and is designed for a specific make and model of equipment. Below are some examples of our equipment drawings we have available.

Caterpillar D10T

https://www.mammothequipment.ca/caterpillar/Caterpillar%20D10T#gsc.tab=0

Komatsu 830E

https://www.mammothequipment.ca/komatsu/Komatsu%20830E#gsc.tab=0

Liebherr T282

https://www.mammothequipment.ca/liebherr/Liebherr%20T282#gsc.tab=0

Wait there is more! Click here to search for your specific model

https://www.mammothequipment.ca/machinery#

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment