Blog Post

Different types of DPF's?

Ralph Deayton • Dec 09, 2019

What are the different types of DPF's?

Mammoth Equipment

has developed passive DPF (Diesel Particulate Filter) systems for most makes and model of underground mining equipment.

A passive DPF means that they rely strictly on existing exhaust gas temperature to regenerate and don’t rely on an additional heat source.

In addition to reducing harmful and toxic gases, a DPF’s primary function is to reduce diesel particulate matter (DPM) also known as soot. The process of regeneration is the conversion of soot into ash in view of the filter not plugging up too quickly and to provide the maximum number of hours of equipment usage between maintenance.

For this, we have a full (98% reduction) wall-flow DPF system for high duty cycle equipment and a partial (30-50% reduction) flow-through DPF system for low duty cycle equipment

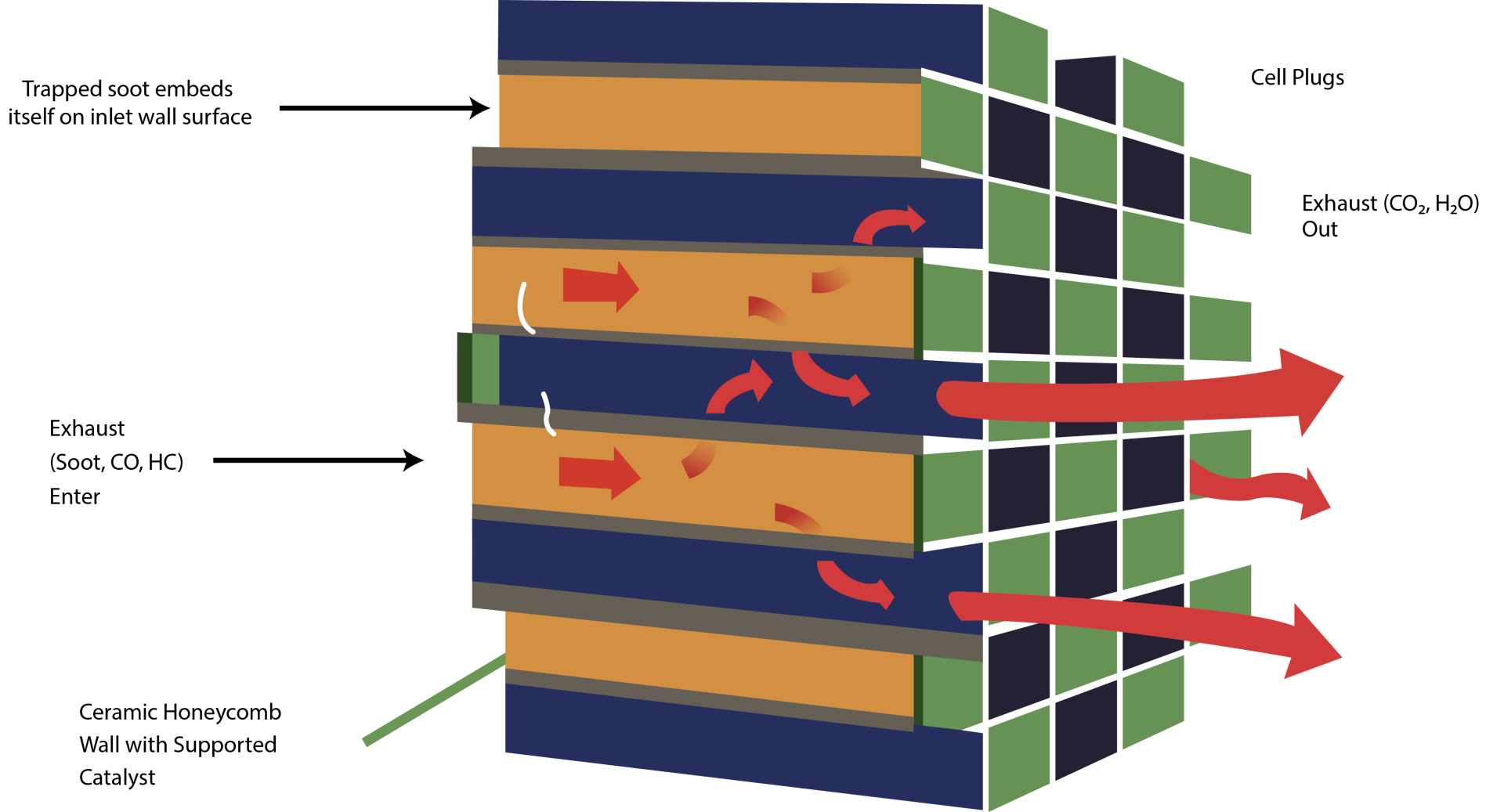

Full Wall-Flow DPF Systems

This system is a 3-part system made up of a catalyst (DOC – Diesel Oxidation Catalyst), a wall flow filter and an outlet/tailpipe.

The wall flow filter will be either a cordierite or a silicon carbide filter substrate and successfully traps 98% of the diesel particulates regardless of whether the engine is hot or cold. The soot is trapped in the porous side walls of the filter when the engine is idling or running at a low speed/load.

When the exhaust gas gets up to operating temperature (typically in excess of 320°C) regeneration occurs and the soot is converted to ash. With the filter loading during idling, low temperature, back pressure in the exhaust system will increase but then as regeneration occurs will drop back down to the typical operating level.

By installing a simple back pressure monitoring system the operator and mechanical team can easily monitor the health and performance of the filter.

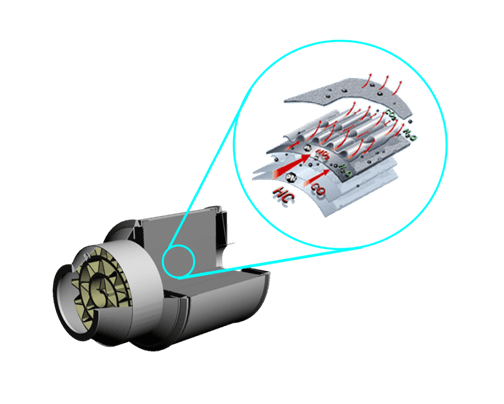

Partial Flow-Through DPF Systems

This system is built very similarly to the Full Wall-Flow system. However, the centre filter section is a flow through design.

This filter section is typically made using a sintered metal design. As a flow through design, there is almost no risk of this filter ever plugging up and this makes it great for equipment with a low duty cycle. The filter efficiency improves as the operating temperature of the equipment increases and can achieve up to 50% DPM reduction.

The team at Mammoth Equipment will work with you to assist you in making the best DPF choice for your equipment based on the specific duty cycle of that unit.

Contact Us Today!

Others points of interest:

Resources:

Share

Tweet

Share

Mail

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment

By Ryan Johnson

•

27 May, 2022

Whether you are a heavy equipment fitter, a mobile maintenance mechanic or a mobile maintenance superintendent , you know the work and time that goes into keeping the heavy diesel mobile equipment operational at your site. Maintenance can be planned or unexpected and involves many different projects, some of which are listed below: Haul Truck Rebuilds Preventative Maintenance Engine Changes Does your site have engine changes or complete rebuilds scheduled soon? Here is one thing our customers have been asking for:

By Ryan Johnson

•

11 Feb, 2022

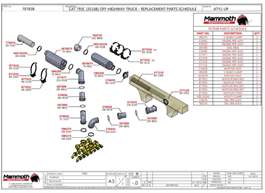

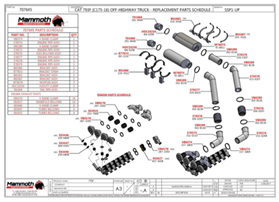

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793C haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 156-6237 2W-9078 156-6247 8X-3361 8X-3360 8X-3135 7C-3337 155-0528 242-8869 8X-3142 Mufflers 7E-6811 Brackets 8X-3130 8X-5103 8X-2850 8X-3128 8X-3132 Clamps 1W-4161 2W-8851 7E-8452 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793F haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 311-6213 311-6204 319-6019 311-6207 319-5307 291-9649 Flex Bellows 306-0297 Mufflers 7E-6811 Brackets 319-5918 293-7616 8X-3130 319-5912 Clamps 302-8136 337-1809 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793D haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the 3516B engine. This includes: Pipes 250-6082 250-6083 250-6084 250-6085 242-8869 8X-3142 Flex Bellows 242-0799 Mufflers 7E-6811 Brackets 8X-3130 242-0792 242-0783 Clamps 302-8136 1W-4161 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.