Blog Post

Mammoth – Aftermarket Exhaust System to Improve Equipment Uptime

Surface Mining Team • Jan 15, 2021

Fixing weak spots in equipment exhaust systems

Are you facing issues running your diesel mobile mining equipment because of weak exhaust systems?

If that’s the case, you are the customer that we can help. At Mammoth, we hear this complaint from several of our customers working in high-production mining and heavy-duty construction environments.

So, what’s the crux of the problem that keeps affecting your equipment performance, reducing its productivity on-site? If you’re an experienced mechanical professional, you might have already figured out the products that are weak and are causing the problems.

While the exhaust bellows are one of the most important parts and an integral component contributing to your equipment’s operation, it is often overlooked when evaluating your engine performance.

Due to its constant flexing, the flex bellow ends up being the weak link in your exhaust system, causing premature failures.

Exhaust Components That May Be Causing Unexpected Downtime

Here are a few exhaust system parts we have engineered to overcome deficiencies that lead to premature failure and equipment downtime. Do any of the weaknesses listed below sound familiar?

Exhaust Bellows –

o Premature failure

o Expensive downtime

Mufflers –

o Lighter gauge steel material is used

o Cracking occurs

Exhaust Pipes –

o Designed and built for longevity

Exhaust Blankets –

o Exposed fiberglass leading to itchy job for mechanics

o Gaps between blankets and not fully covering the exhaust system

o Not reusable

The Solution - Mammoth Exhaust System

Here are a few exhaust system parts we have engineered to overcome deficiencies that lead to premature failure and equipment downtime. Do any of the weaknesses listed below sound familiar?

Mammoth Equipment & Exhausts has been working for years on improving weak spots in heavy mobile equipment exhaust systems. We listened to our customers and provided a solution to their needs and as a result have built up an extensive library of equipment drawings.

If you are looking for a solution to a deficiency in your equipment’s air intake or exhaust system – we can help. Contact our team today and find out if we have a solution for this already and if not, we will work with you to get one.

We have an in-house design and development team ready for the next challenge.

For further information regarding Mammoth’s aftermarket exhaust systems and replacement parts, you can contact us

Phone – 800-854-8291

Submit form online - contact us

Share

Tweet

Share

Mail

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment

By Ryan Johnson

•

27 May, 2022

Whether you are a heavy equipment fitter, a mobile maintenance mechanic or a mobile maintenance superintendent , you know the work and time that goes into keeping the heavy diesel mobile equipment operational at your site. Maintenance can be planned or unexpected and involves many different projects, some of which are listed below: Haul Truck Rebuilds Preventative Maintenance Engine Changes Does your site have engine changes or complete rebuilds scheduled soon? Here is one thing our customers have been asking for:

By Ryan Johnson

•

11 Feb, 2022

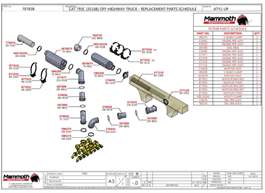

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793C haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 156-6237 2W-9078 156-6247 8X-3361 8X-3360 8X-3135 7C-3337 155-0528 242-8869 8X-3142 Mufflers 7E-6811 Brackets 8X-3130 8X-5103 8X-2850 8X-3128 8X-3132 Clamps 1W-4161 2W-8851 7E-8452 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

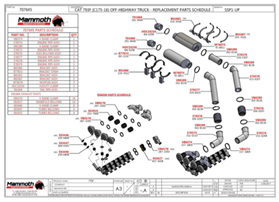

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793F haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 311-6213 311-6204 319-6019 311-6207 319-5307 291-9649 Flex Bellows 306-0297 Mufflers 7E-6811 Brackets 319-5918 293-7616 8X-3130 319-5912 Clamps 302-8136 337-1809 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793D haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the 3516B engine. This includes: Pipes 250-6082 250-6083 250-6084 250-6085 242-8869 8X-3142 Flex Bellows 242-0799 Mufflers 7E-6811 Brackets 8X-3130 242-0792 242-0783 Clamps 302-8136 1W-4161 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.