Blog Post

How To Install Thermal Exhaust Blankets

Ralph Deayton • Nov 20, 2019

How Do You Install A Thermal Exhaust Blanket?

Thermal exhaust blankets are vital in keeping employees safe, whether it’s by protecting them from the hot exhaust, or the high

surface temperatures of engine parts, or reducing the risk of a fire and heat exhaustion on the mobile equipment.

But how are these exhaust blankets (or otherwise known as exhaust wrap) installed onto the components of a mobile machine so they can prevent these risks from happening?

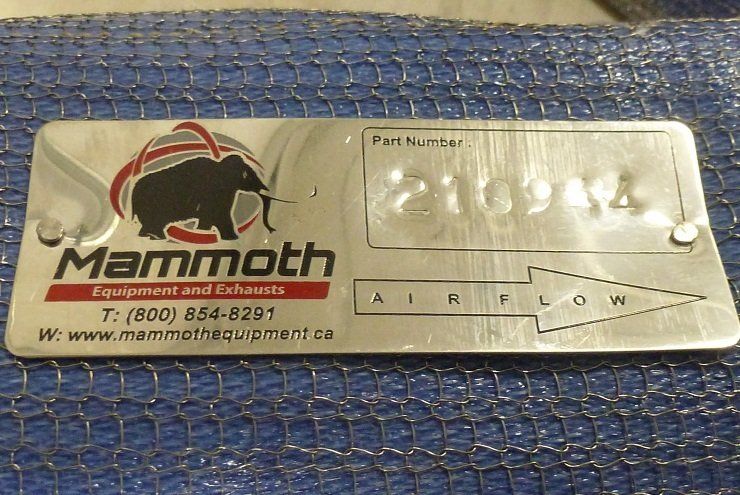

Mammoth's Thermal Exhaust Blankets

Mammoth Equipment provides thermal blankets that wrap around the turbo, the manifold and all the way through to the tailpipe of an exhaust system.

Our thermal exhaust wrap blankets are non-absorbent

(oil, fuel, grease and moisture resistant), they are not itchy (extra layers of cloth completely enclose the fiberglass layer), and they are machine specific made.

We manufacture the PyroGard blanket heat wrap to fit your specific machine, model and engine.

You may be interested in seeing our Online Library

- request access to our library to cross reference OEM part #'s

The Installation Process...

For this example, we will be demonstrating how to install a turbo blanket.

Step 1: Know where each blanket goes before installing. In this case, we are installing a turbo blanket, so it will be wrapping around the turbo.

Step 2: Using gloves, unwrap and fit the blanket around the turbo.

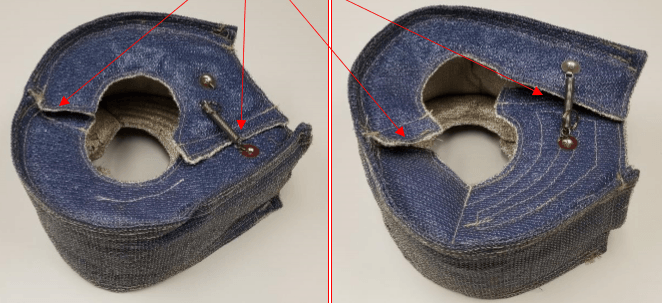

Step 3: Form the turbo blanket so the seams overlap as shown below. Follow this step for both sides of the blanket.

Read on for the next steps, or pause and watch our video here on how to install a turbo blanket

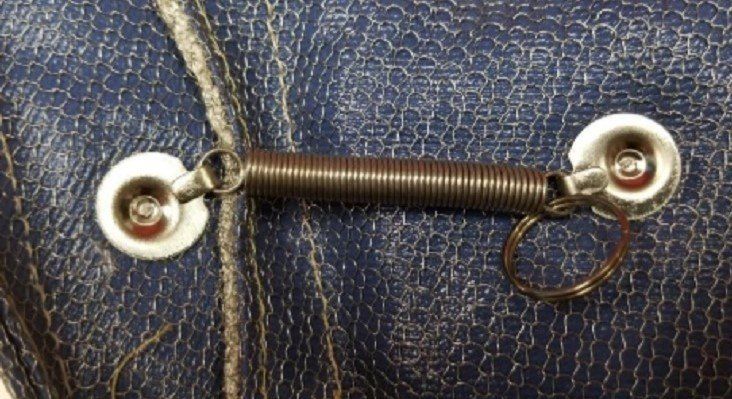

Step 5: Double check the spring on each side of the blanket is fastened to two clamps.

Step 6: And just like that, you have installed a turbo blanket!

Installing blankets on your machine will ensure that the safety of those working near or on the equipment is not put in danger, whether its lowering the touch surface of the exhaust parts or reducing the risk of a potential thermal incident from occurring.

WATCH OUR VIDEO TO LEARN MORE ABOUT MAMMOTH'S PYROGARD BLANKETS:

Share

Tweet

Share

Mail

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment

By Ryan Johnson

•

27 May, 2022

Whether you are a heavy equipment fitter, a mobile maintenance mechanic or a mobile maintenance superintendent , you know the work and time that goes into keeping the heavy diesel mobile equipment operational at your site. Maintenance can be planned or unexpected and involves many different projects, some of which are listed below: Haul Truck Rebuilds Preventative Maintenance Engine Changes Does your site have engine changes or complete rebuilds scheduled soon? Here is one thing our customers have been asking for:

By Ryan Johnson

•

11 Feb, 2022

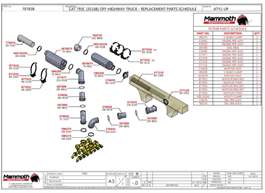

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793C haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 156-6237 2W-9078 156-6247 8X-3361 8X-3360 8X-3135 7C-3337 155-0528 242-8869 8X-3142 Mufflers 7E-6811 Brackets 8X-3130 8X-5103 8X-2850 8X-3128 8X-3132 Clamps 1W-4161 2W-8851 7E-8452 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

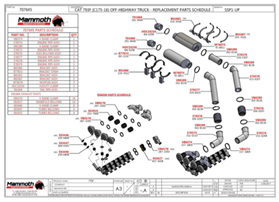

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793F haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 311-6213 311-6204 319-6019 311-6207 319-5307 291-9649 Flex Bellows 306-0297 Mufflers 7E-6811 Brackets 319-5918 293-7616 8X-3130 319-5912 Clamps 302-8136 337-1809 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

By Ryan Johnson

•

11 Feb, 2022

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793D haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the 3516B engine. This includes: Pipes 250-6082 250-6083 250-6084 250-6085 242-8869 8X-3142 Flex Bellows 242-0799 Mufflers 7E-6811 Brackets 8X-3130 242-0792 242-0783 Clamps 302-8136 1W-4161 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.